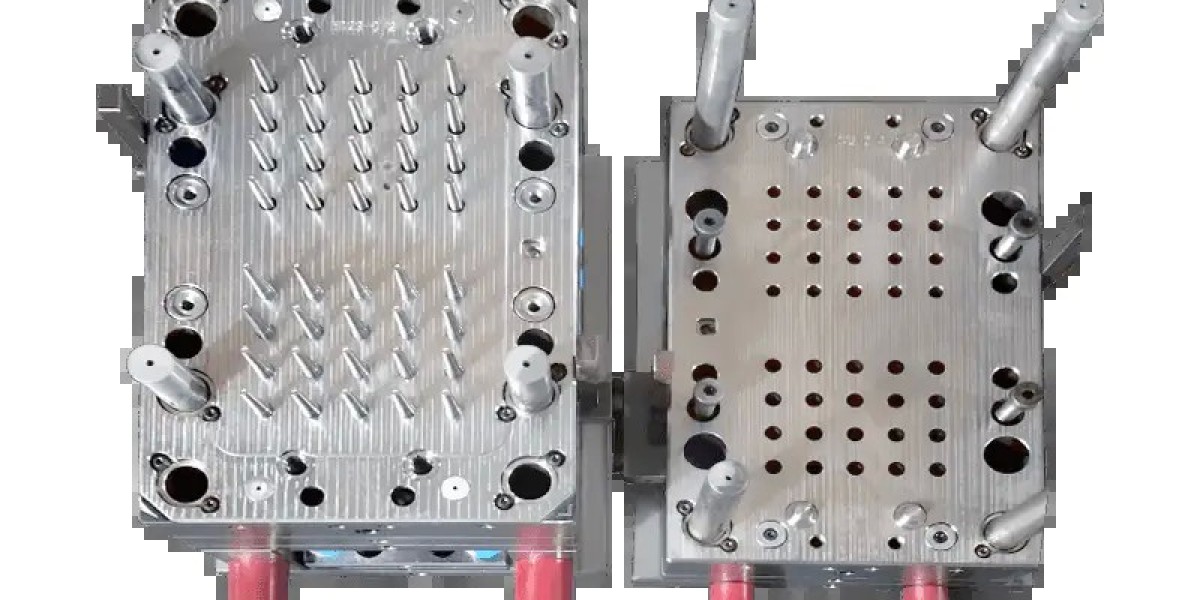

Medical device injection molds are specialized tools designed for the high-precision manufacturing of medical devices. These molds are integral to the production process, ensuring that the final products meet stringent quality and safety standards required in the healthcare industry. The molds are crafted to produce components with complex geometries and exacting tolerances, which are critical for the functionality of medical devices such as syringes, catheters, and diagnostic tools.

The functionality of medical device injection molds extends beyond mere shape replication. They are engineered to facilitate the incorporation of intricate features like threads, ribs, and channels, which are often necessary for the proper operation of medical equipment. Additionally, these molds are capable of producing parts with a high degree of repeatability, which is essential for maintaining consistency across batches, a key factor in regulatory compliance.

Moreover, medical device injection molds are often constructed from materials that can withstand the rigors of sterilization processes, such as autoclaving, and are compatible with the materials used in the devices themselves, such as various grades of plastic and biocompatible resins. This compatibility ensures that the molds do not introduce any contaminants or alter the properties of the medical devices during the molding process.

In summary, medical device injection molds play a pivotal role in the healthcare sector, enabling the production of reliable and safe medical devices that are vital for patient care and treatment. Their precision, durability, and compatibility with medical-grade materials make them indispensable in the manufacturing of life-saving equipment.