The Plastic Fork Mold by Yongkang Huashun Mould Co., Ltd. offers a precise and efficient solution for the production of disposable plastic cutlery. Designed to meet the demands of high-volume manufacturing, this mold series delivers consistent results and reduces production times, making it an excellent choice for businesses focused on quality and productivity.

Faster Production with Shorter Cycles

One of the standout features of the Disposable Plastic Knife Fork and Spoon Mould Series is its rapid molding cycle, which ranges from 6 to 8 seconds. This short cycle time ensures quick turnaround, enabling manufacturers to produce large quantities of forks, knives, and spoons efficiently.

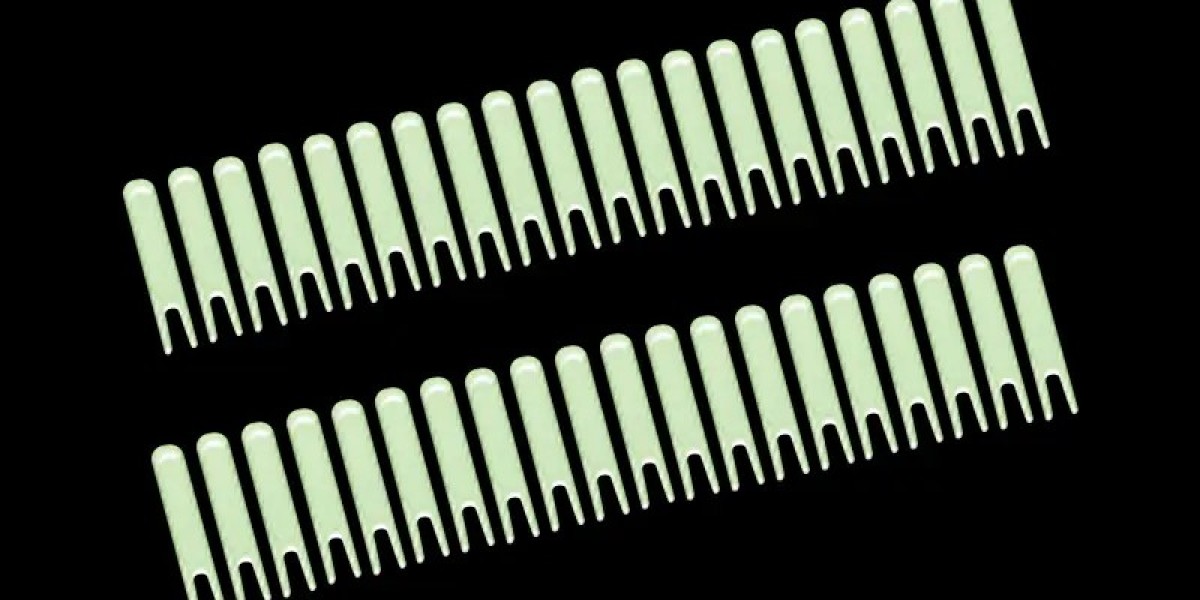

Equipped with high-capacity molds that include options for 32 or 48 cavities, the series is ideal for businesses requiring bulk production. These molds are also optimized for thin-walled injection molding, ensuring lightweight yet durable cutlery that uses less material without sacrificing strength.

Precision and Consistency in Manufacturing

Precision is critical in the production of disposable cutlery, and this mold series excels in delivering uniform results. The detailed engineering ensures every piece of cutlery meets strict quality standards, reducing waste and maintaining product consistency.

The molds are compatible with a variety of plastic materials, such as PS and PP, providing flexibility in production. This adaptability allows manufacturers to tailor products to specific customer needs, whether they prioritize lightweight designs or enhanced durability.

Cost-Efficient Solutions for Businesses

The Disposable Plastic Knife Fork and Spoon Mould Series is designed to minimize production costs while maintaining high-quality output. By reducing material waste through efficient mold design and optimizing the production process, manufacturers can achieve significant cost savings.

Additionally, the high level of automation in these molds reduces the need for manual intervention, lowering labor costs and accelerating production. This allows businesses to allocate resources more effectively while boosting overall productivity.

Durable Construction and Versatile Applications

Built for high-volume operations, the molds feature robust construction using premium materials, ensuring durability and consistent performance over time. Their resilience makes them a reliable tool for continuous production, reducing the need for frequent maintenance or replacement.

The versatility of this mold series is another advantage. With multiple cavity options and compatibility with various materials, these molds can support diverse production requirements, whether for food service, retail, or custom applications.

Why Choose Disposable Plastic Fork Mold?

This mold series combines precision engineering with efficient production capabilities, making it a practical choice for businesses looking to enhance their manufacturing processes. With a focus on reducing waste, increasing output, and maintaining high standards of quality, these molds meet the demands of modern production environments.

Explore how the Plastic Fork Mold can elevate your production efficiency and deliver consistent results for your business. By choosing solutions that emphasize reliability and adaptability, you can achieve both operational excellence and customer satisfaction.