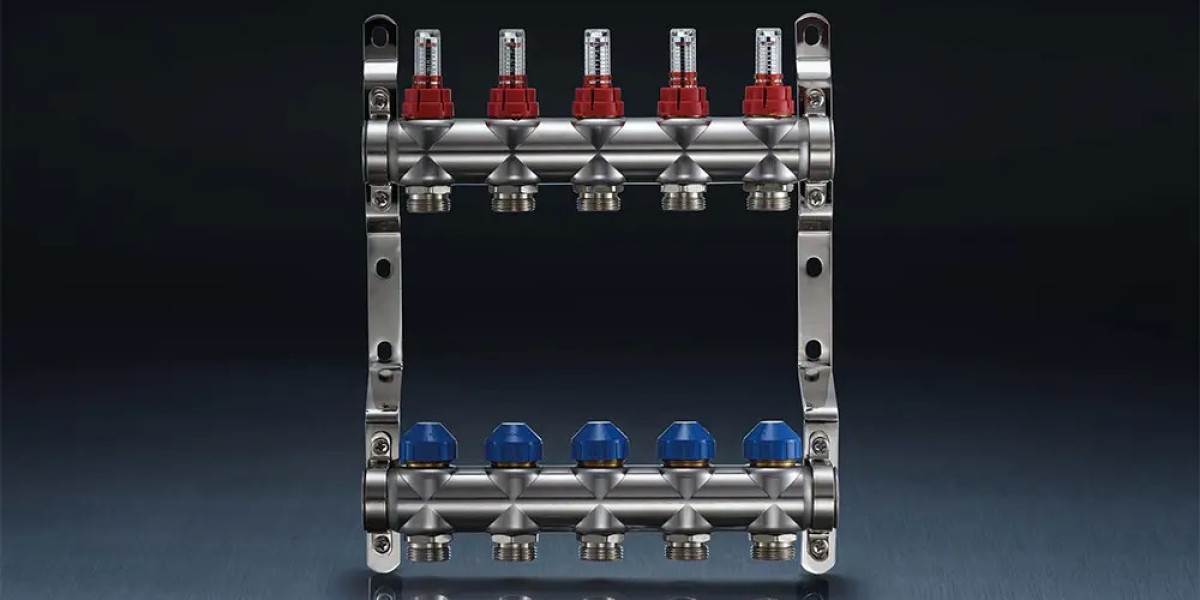

In modern industries, where efficiency and reliability are paramount, Stainless Steel Manifold has emerged as a cornerstone of fluid and gas distribution systems. These manifolds are designed with precision engineering, offering unmatched durability and performance across diverse applications. Whether used in industrial systems or commercial setups, their role in optimizing operations cannot be overstated.

What Makes Stainless Steel Manifolds Essential?

A stainless steel manifold isn’t just another component—it’s a vital link in maintaining the flow and distribution of liquids and gases. Designed with high-grade materials, these manifolds ensure a balance of strength and flexibility, capable of performing under extreme temperatures and pressures. Their applications extend from heating systems to complex industrial processes, showcasing versatility in functionality.

The Stainless Steel Manifold is particularly suited for industries where corrosion resistance and durability are key. For example, in the food and beverage sector, its hygienic properties make it an ideal choice for distributing water, milk, and other beverages.

Key Features of the JL-B7072 Stainless Steel Manifold

Medium Temperature Range and Pressure Tolerance

The JL-B7072 model operates efficiently within a medium temperature range of -20°C to 110°C, ensuring compatibility with various environments. It can also withstand a maximum working pressure of 2 MPa (20 bar), making it robust enough for demanding systems.Customizable Dimensions

Available in a range of sizes, the JL-B7072 manifold offers configurations such as:- 1” G2 inlet with multiple outlet options (1-7 outlets).

- Compact design with a height of 210 mm, ensuring compatibility with space-limited setups.

Material Strength

Constructed from premium stainless steel, this manifold offers exceptional durability and resistance to wear, even under continuous use. Its smooth surface resists buildup, facilitating easy cleaning and maintenance.

Applications Across Industries

Industrial Systems

The stainless steel manifold is indispensable in industries like chemical processing and manufacturing. Its precision-engineered design ensures the efficient flow of fluids and gases, reducing the risk of leaks and maintaining consistent pressure.

Commercial HVAC Systems

In heating and cooling systems, the manifold optimizes the distribution of fluids, enhancing the efficiency of HVAC operations. Its ability to resist corrosion ensures a longer lifespan, reducing maintenance costs over time.

Food and Beverage Production

Hygiene is critical in the food and beverage sector. The manifold's easy-to-clean design and non-corrosive material make it a trusted choice for systems requiring stringent cleanliness standards.

Why Choose Stainless Steel?

The inherent properties of stainless steel make it a reliable material for critical systems. It resists oxidation and chemical degradation, ensuring that the Stainless Steel Manifold performs consistently over time. Additionally, its strength supports the efficient handling of high-pressure systems, reducing operational downtime and ensuring smooth functionality.

Conclusion

The Stainless Steel Manifold, including the JL-B7072 model, exemplifies the advantages of integrating durable, efficient, and versatile components into fluid and gas distribution systems. Whether you're optimizing industrial processes or maintaining a commercial HVAC setup, these manifolds offer solutions that meet your needs with reliability and precision.

Explore the full range of options and configurations on our official website to discover how our stainless steel manifolds can elevate your system’s performance.